Plant Layout and Facility Design Solutions

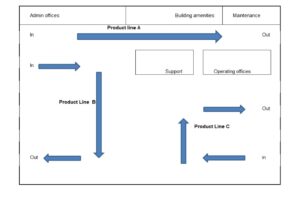

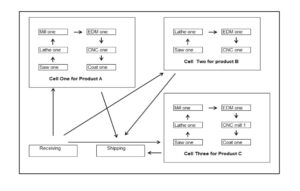

Arrangement of people, materials, and equipment is at the very heart of business productivity; whether called floor plan, layout, or design; it can improve product flow, space utilization, throughput and capacity utilization, in a factory, plant, DC, lab. Dynamic organizations of any size, engaged in just about any endeavor, will routinely practice rearrangement.

JPR offers plant layout and facility design solutions, to assist to make informed decisions when changing your facility’s arrangement. Layouts don’t happen often, so those skills may not be at hand.

Types of Layout and Design Changes

Change to building layouts and production facilities is to be expected for a dynamic organization. Your own challenges and useful approaches may be similar to these:

• Relieve a jam-packed facility: The key is to maintain output during rearrangement, so a resolution should create both short- and long-term options. Target problems with layout technique, then perform moves in a checkerboard sequence, one step at a time.

• Create better flow, or more output, with today’s product mix: Variables include the the geometry of the facility and work sequence of course, but also workplaces, equipment, and products; constraints management; batch sizes; volume and inventory policy. A good layout will provide some open space to facilitate short-term change and general paths for future expansion.

• Add output and capacity and facilitate new products: Resolve current problems and prepare for new technology, products, and volumes. Physical arrangements aren’t revised frequently, so your layout changes shouldn’t just catch up, but also anticipate the future.

• Rearrange to cut through a wasteful “Spaghetti” flow: Good flow is routinely a prime objective for all layout projects, along with space utilization. Here, layout practices can definitely cut waste as well as increase efficiency and output. Don’t overlook the opportunity to review constraints, crewing, in-process inventory, and material handling concurrently.

• Acquire or consolidate operations or facilities, shut down obsolescent plants, or upgrade buildings and equipment: Start up a new operation, instead of or in addition to, large or small, locally or in a new community. Facility planning requires extensive layout and option analysis; of a general nature first, then in detail to arrange and fit in the chosen process. Watch out for the permitting process and the time it requires. And for the demands of Fire Marshals.

• Find a site for a new facility with qualified labor and low operating and distribution costs: To provide data for a decision, quantify in advance of a decision the expected acquisition and operating costs in candidate communities, and define what suitable property is available for the shortlist. This step must be done very confidentially; an organization has more leverage over prices while its identity is not known.

• Re-shore production to US facilities: Move production to US facilities, whether due to world events, tariffs, boycotts, or political pressure or extended cycle times, communication, malware, transportation, or fixed cost of inventory. Re-shoring will be tough, and there are numerous factors to resolve, but sooner or later, you will have to determine where to produce the product and how. JPR can help.

• Office layouts: Offices are a special layout case because they usually are quite visible and affect both clients and executives. With social distancing and perhaps remote workplaces in the mix, the options have increased.

What’s Next?

Is there a single, straightforward solution to all, or perhaps the majority, of the layout puzzles? Of course not. Because no two facilities or processes are alike, there will be no online template or conventional floor design to fit your needs.

Contact Jackson Productivity Research for a consultation to learn about creating a productive layout for your specific challenges, circumstances, timing, and budget.

Email jack@jacksonproductivity.com, or call 843-422-1298.